inertia test bench

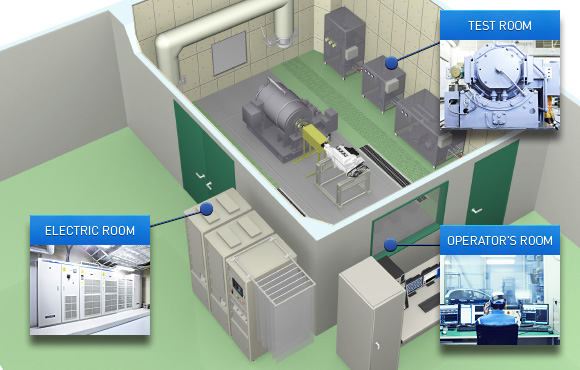

Identification and Robustness Analysis of Powertrain Excitation Forces. Test bench system architecture.

Heavy Duty Scissor Lift Tables Capacity 500kg To 1250kg Scissor Lift Lift Table Heavy Duty Scissors

This work presents a new systematic solution to identify the vehicle inertia parameters which are essential inputs for vehicle simulation and vehicle safety research.

. 1 simulation working condition inertia experiment bench and an experiment method. Low inertia hub dyno or axle-mounted dynamometer. Download scientific diagram The moment of inertia test bench.

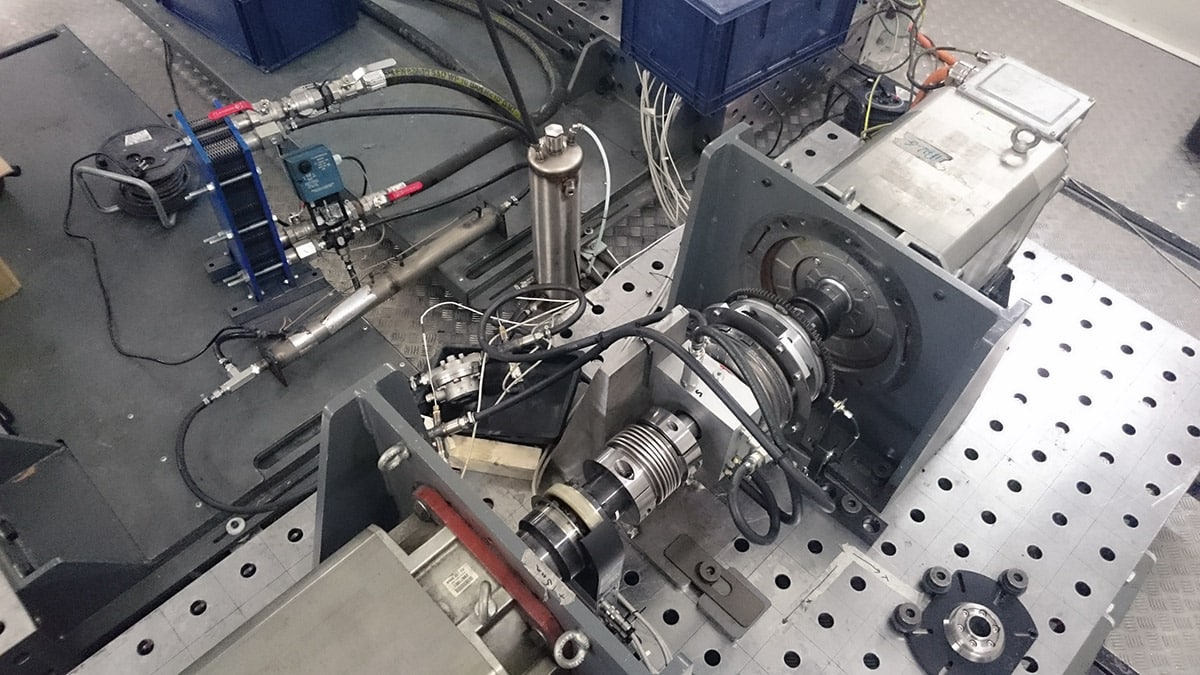

The brake disc clamping device comprises a motor and a brake force arm rod wherein the motor is connected with a group of inertia discs the inertia discs are connected through a main shaft the main shaft is supported through a support frame the main shaft is connected with a brake disc. Зарегистрироваться Войти Войти через Facebook Войти через Google. The test bench works by imposing by way of a hydraulic system a motion to a load cell to which the test specimen is rigidly attached.

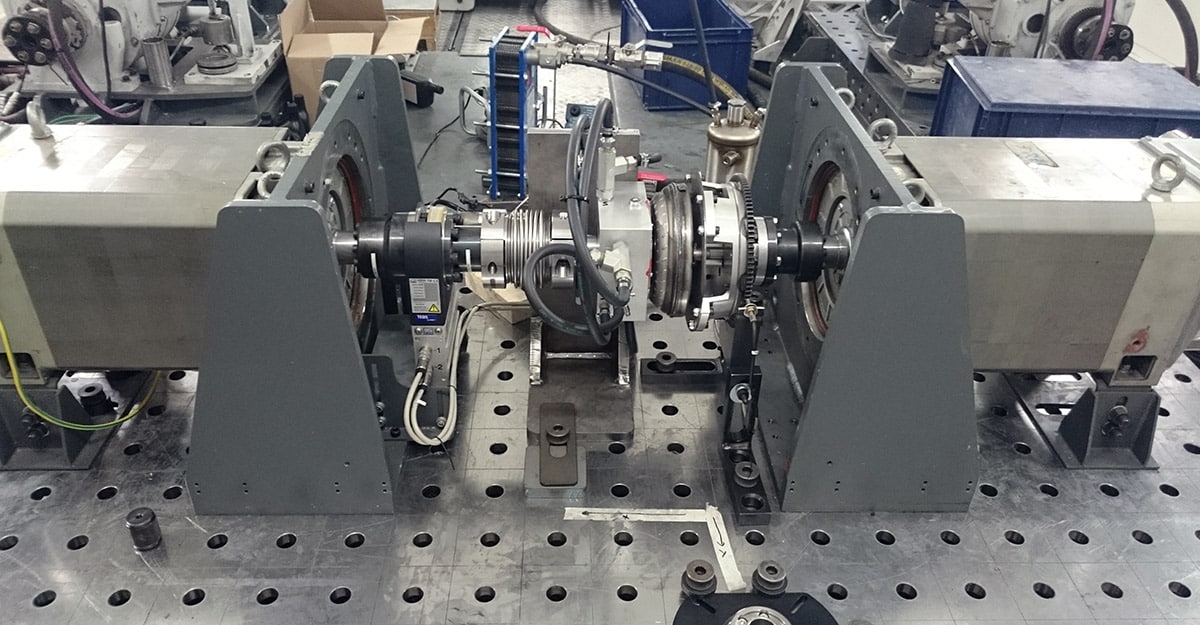

The inertia parameters are evaluated by measuring the specimen motion law together with forces and torques that the test specimen transmits to the motion system through the load cell. Inertia flywheel is a mechanical device specifically designed to efficiently store rotational energy. The Brake Inertia Dynamometer is arranged in-line with the main elements being flywheel assemblies brake test area DC or AC machine and a disc brake.

Translations in context of inertia test in English-Russian from Reverso Context. CN-105444949-A chemical patent summary. However these testing methods are either entirely unable to simulate dynamical conditions close to real driving maneuvers or they can do so approximately only at very high costs.

To make the engine an idling state a dynamometer must be controlled so that the engine becomes no-load state. The small high-speed motor test bench test system is used to test low-power high-speed motors mainly for the low-power aviation generators robot motors small high-speed compressor motors machine tool spindle motors etc. Construction of the Brake Inertia Dynamometer A system of flywheels is mounted onto a common central shaft to simulate the mass of the test vehicle.

The installation platform can be designed according to the motor to be tested and the end flange installation. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Of a vehicle engine.

Скачать версию для Windows. NewBeeDrone Inertia freestyle Cinematic FPV Frame. In these tests there is a process that the engine must become an idling state.

Flywheels resist changes in rotational speed by their moment of inertia. Figure 1 shows a typical mechanical configuration of the engine test bench. Has not to be carried out on a vehicle submitted for type approval if the braking system components are tested on an inertia test bench to meet the prescriptions of annex 4 paragraphs 152.

Nowadays inertia dynamometers or roller dynamometers are used for the development and testing of vehicle brakes. The Low inertia hub dyno or axle-mounted dynamometer consists of the mobile low-inertia AC dynamometer dynamometer inverter battery simulator electrical control cabinet measurement sensors vehicle windward cooling system traffic real-life simulation system master computer. Perfect test system and good test facility are the premise and the foundation to guarantee the product qualityIt can improve research and develop level elevate brake technical and develop friction material theory according to the research of automobile detent inertia test.

In conceptual design phase of this work a virtual three Degree-of-Freedom DoF test bench parallel manipulator PM whose moving platform is used to clamp vehicle under test is. Download Citation Inertia compensasion control of engine test bench An engine test bench is utiliezed to execute a performance test durability test and etc. The automobile detent is essential equipments relate to the traffic safety whose quality is very important.

The Type-I test according to annex 4 paragraph 15. An engine test bench is utiliezed to execute a performance test durability test and etc.

Instrumented Test Bench 1 Motor To Test 2 Brake 3 Tank 4 Download Scientific Diagram

Car Power Test Benches Easyrun Technology

Engine Bench System Testing Systems Meidensha Corporation

An Overview Of The Inertia Dyno Bench Setup With Its Important Parts Download Scientific Diagram

Electric Motor Test Bench Motorline Mli C Mea Testing Systems Ltd Torque Friction Dynamic

Schematic Drawing Of Test Bench Component Labelled Thermal Energy Download Scientific Diagram

Semi Natural Modeling Test Bench For The Small Satellites Adcs

Car Power Test Benches Easyrun Technology

Engine Bench System Testing Systems Meiden Europe Gmbh

Engine Test Bench Download Scientific Diagram

0 Response to "inertia test bench"

Post a Comment